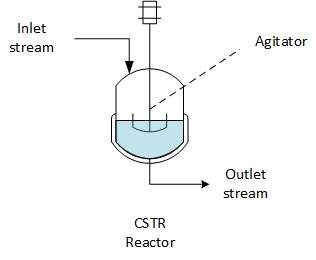

CSTR --- Continuous Stirred Tank Reactor

Anaerobic microorganism treatment is an indispensable treatment section in the current high concentration organic wastewater sewage water treatment process. It is better that aerobic microorganism treatment not only has low energy consumption, but also can produce biogas as a secondary use of energy. The higher the anaerobic reaction volume load is, the higher the oxygen reaction is, and the lower the investment is for treating the same amount of COD anaerobic reaction.

At present, the commonly used anaerobic treatment processes include:

UASB --- Up-flow Anaerobic Sludge Bed/Blanket

EGSB --- Expanded Granular Sludge Blanket Reactor

CSTR --- Continuous Stirred Tank Reactor

IC --- Internal Circulation Anaerobic Reactor

ABR --- Anaerobic Baffled Reactor

UBF --- Upflow Sludge Bed Filter

AF --- Anaerobic Biofilter

AFBR --- Anaerobic Fluidized Bed Reactor

USSB --- Upflow Staged Sludge Bed

AAFEB --- Anaerobic Attached microbial Film Expanded Bed

USR --- Upflow solid anaerobic reactor

PPR --- Plug Flow Reactor

Two-phase Anaerobic Reactor

CSTR --- Continuous Stirred Tank Reactor

CSTR is short for Continuous Stirred Tank Reactor,is an anaerobic treatment technology that makes fermentation materials and microorganisms in a completely mixed state.

The CSTR is equipped with a stirring device in the conventional digester to make the fermentation raw materials and microorganisms in a fully mixed state. Compared with the conventional digester, the active zone is distributed throughout the reactor, and its efficiency is significantly improved compared with the conventional digester, so it is called the high-speed digester.

The digester adopts continuous constant temperature, continuous feeding or semi continuous feeding operation, and is applicable to the treatment of high concentration and large amount of suspended solid raw materials. In the digester, the newly entered raw materials are quickly mixed with all the fermentation liquid in the fermentation tank due to the stirring effect, so that the fermentation substrate concentration is always kept relatively low, while the discharged feed liquid is equal to the substrate concentration of the fermentation liquid, and the microorganisms are also discharged at the time of discharge, so the discharge concentration is generally high. The digester is a typical HRT (hydraulic retention period), SRT and MRT digester that are completely equivalent. In order to keep the proliferation and flushing speed of slow growing methanogens in balance, the HRT is required to be longer, generally 10 to 15 days or longer.

Principle of CSTR

The fermentation of feed liquid and the generation of biogas are completed in a closed tank. A stirring device is installed in the digester to make the fermentation raw materials and microorganisms in a completely mixed state. Feeding mode adopts constant temperature continuous feeding or semi continuous feeding operation. The newly entered raw materials are quickly mixed with all the fermentation liquid bacteria in the fermenter due to the stirring effect, so that the concentration of fermentation substrate is always kept relatively low, so as to degrade the organic pollutants in the wastewater and remove the suspended solids from the anaerobic wastewater biological processor.

Advantages of CSTR

1.The process can enter raw materials with high suspended solids content;

2.The materials in the digester are evenly distributed, avoiding the layered state, and increasing the contact opportunity between the substrate and microorganisms;

3.The temperature distribution in the digester is uniform;

4.Any inhibitory substance entering the digestive apparatus can rapidly disperse and maintain the lowest concentration level

5.The scum crusting, blockage, poor gas escape and channeling phenomenon are avoided.

Applications of CSTR

It is applied to slaughter wastewater, livestock and poultry manure treatment in cattle, pigs, chickens and other breeding farms, and biogas production and power generation projects; High concentration organic wastewater treatment project with more SS such as urban domestic sludge.

#QDEVU #WATERTREATMENT #WASTEWATERTREATMENT #SEWAGETREATMENT #SEWAGEWATERTREATMENT #BIOLOGICALTREATMENT #ANAEROBICPORCESS

Visit www.evuchina.com for more informations!